Processing Cord Blood Units

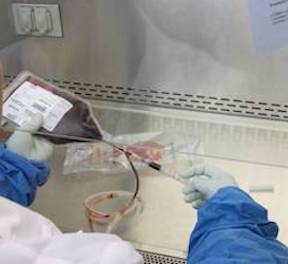

Following collection, the cord blood unit (CBU) is transported to the CCBB Processing Laboratory at Duke University. The units are packaged in a specially designed container, and must reach the CCBB within 45 hours from collection. All processing in the CCBB laboratory is performed in a functionally closed system in a controlled environment serviced by a qualified HVAC system.

Upon receipt at the CCBB Processing Laboratory, several label verification steps are performed to ensure identity of the unit. Then, a sample of cord blood is obtained from a syringe port on the collection bag. The sample is analyzed, and the total nucleated cell count (TNCC) is calculated. Some of the sample is reserved for future analysis if the unit qualifies for processing.

CBU separation

Technicians then use an automated process to separate the CBU into its 3 components (CBU product, red blood cells, and plasma). A post-processing sample is taken, and if the unit meets all of the specifications it is prepped for cryopreservation (freezing).

In preparation for cryopreservation, a specialized cryoprotectant called DMSO is added to the CBU to safeguard the cells while in liquid nitrogen storage. Then, a protectant layer of overwrap covers the CBU to prevent any possibility of cross contamination while stored in the liquid nitrogen freezer.